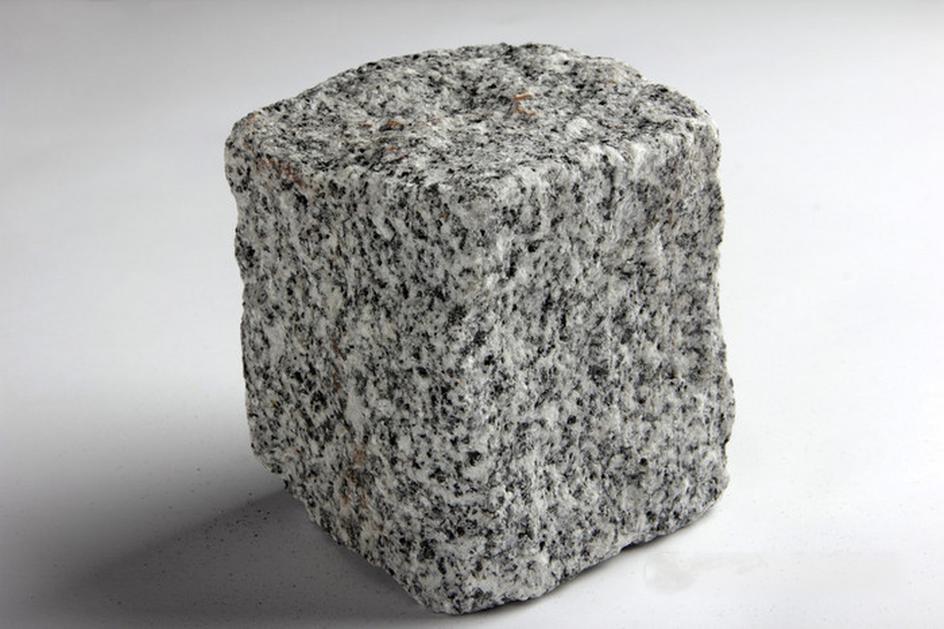

Granite Powder Grinding Mill Machines

Granite powder grinding mill machines are industrial tools used to break down granite rock into fine powder.

Granite, renowned for its durability and aesthetic appeal, has transcended its traditional role in construction to become a valuable resource in various industries.

The utilization of granite powder, a byproduct of the stone-cutting process, has given rise to the need for advanced machinery for precision grinding.

This article explores the world of granite powder grinding mill machines, delving into their types, operating principles, and the myriad applications that propel industries forward.

Granite Powder Uses

These machines are crucial in various industries, including:

1. Construction: Granite powder is a key ingredient in some building materials like concrete and artificial stone.

2. Coating: Finely ground granite is used as a filler in paints and coatings, adding texture and durability.

3. Agriculture: Granite dust can be used as a soil amendment, providing essential minerals for plant growth.

4. Glassmaking: Granite powder is used in the production of certain types of glass, adding clarity and strength.

Main types of granite powder grinding mill machines

There are several types of granite powder grinding mill machines, each with its own advantages.

| Images | Names | Operation | Advantages |

| Ball Mill | Utilizing rotating balls within a cylindrical chamber, ball mills crush and grind granite to achieve the desired particle size. | Versatile, suitable for wet and dry grinding, and capable of producing a wide range of particle sizes. |

| Raymond Mill | Utilizing rollers to crush and grind granite, Raymond mills provide a high degree of control over particle size distribution. | Efficient for medium and fine grinding, widely used in various industries. |

| Vertical Roller Mill | Granite is crushed between rotating grinding rollers and a stationary grinding table, providing efficient grinding and classification. | Effective for fine and ultrafine grinding, energy-efficient, and suitable for a range of materials. |

| HGM Series Ultrafine Grinding Mill | Designed for ultrafine grinding, HGM mills use multiple grinding rollers to achieve exceptionally fine particle sizes. | High precision, versatility, and the ability to produce ultrafine powders suitable for diverse applications. |

| Micro Powder Grinding Mill | Focused on producing fine to superfine powders, micro powder grinding mills use a combination of centrifugal force and grinding elements. | Precise control over particle size distribution, suitable for materials with low hardness. |

| Ball Mill with High Alumina Tile Lining | Similar to traditional ball mills but incorporates high alumina tile lining to reduce wear and contamination. | Efficient for ultrafine grinding, particularly suited for materials that may cause excessive wear. |

How to choose granite powder grinding mill machines?

The choice of the right granite powder grinding mill machine depends on several factors, such as the desired particle size, production capacity, budget, and material properties. When choosing a mill, it is important to consider the following:

1. Particle size: The fineness of the powder required for your application will determine the type of mill you need.

2. Production capacity: How much granite powder do you need to produce per hour or per day? This will influence the size and power of the mill you need.

3. Budget: Granite powder grinding mills can range in price from a few thousand dollars to hundreds of thousands, depending on factors like capacity, features, and brand.

4. Material properties: The hardness and moisture content of the granite will also affect the choice of mill.

By carefully considering these factors, you can choose the right granite powder grinding mill machine for your needs.

Shanghai Clirik Machinery Co.,Ltd. specializes in the production of various granite grinding machines, welcome to contact us to get a quote.

WhatsApp: +8613512155195