Basalt Rock Powder Making Machines

Producing basalt rock powder involves several types of machines for crushing, grinding, and classifying the rock into a fine powder. Here is a list of the essential machinery used in this process:

ESSENTIAL MACHINERY:

Primary Crusher:

Jaw Crusher: Suitable for primary crushing of large basalt rocks.

Gyratory Crusher: An alternative for primary crushing, offering higher capacity.

Secondary Crusher:

Cone Crusher: Used for secondary crushing, reducing the size of the basalt further.

Impact Crusher: Can also be used for secondary crushing, producing a finer product.

Hammer Crusher: Suitable for secondary or tertiary crushing to achieve smaller particle sizes.

Screening Equipment:

Vibrating Screens: Used to separate crushed basalt into different size fractions before further processing.

Grinding Mills:

Ball Mill: Uses grinding balls to crush and grind the basalt into a fine powder.

Raymond Mill: Utilizes rollers and a rotating bowl to grind the basalt.

Ultrafine Grinding Mill: Specifically designed for producing very fine powders, achieving particle sizes in the micrometer range.

Classifying Equipment:

Air Classifiers: Used to separate fine particles from coarser ones, ensuring a uniform powder.

Sieves: Used for further screening and separation of particles.

Clirik Crusher And Grinding Mills For Basalt Rock Dust Making

Clirik Machinery is a well-known manufacturer that specializes in the production of various types of grinding mills and crushers, particularly suited for creating fine powders like basalt rock dust. Here’s an overview of Clirik’s equipment suitable for basalt rock dust making:

Clirik Crushers:

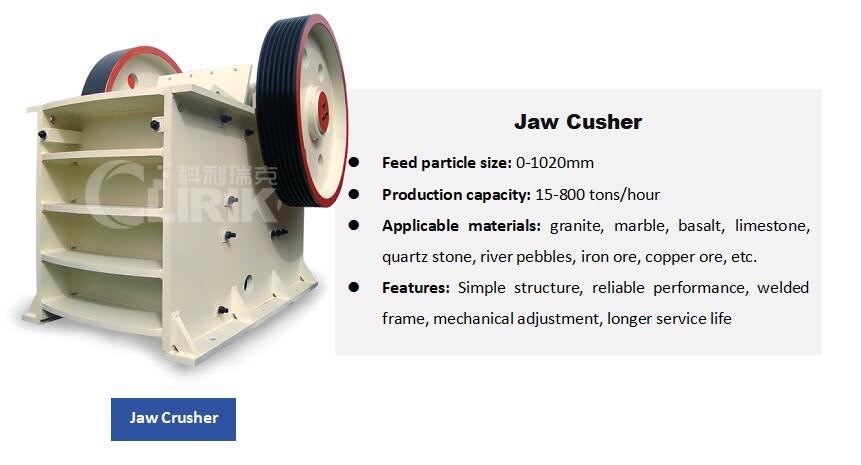

1. Clirik Jaw Crusher:

Model: PE Series Jaw Crusher

Features:

High crushing ratio

Simple structure and reliable operation

Easy maintenance and low operating cost

Suitable for primary crushing of basalt rock

2. Clirik Cone Crusher:

Model: HCS Series Cone Crusher

Features:

High performance and productivity

Hydraulic pressure system

Advanced crushing principle and technical data

Suitable for secondary and fine crushing of hard and medium-hard rocks

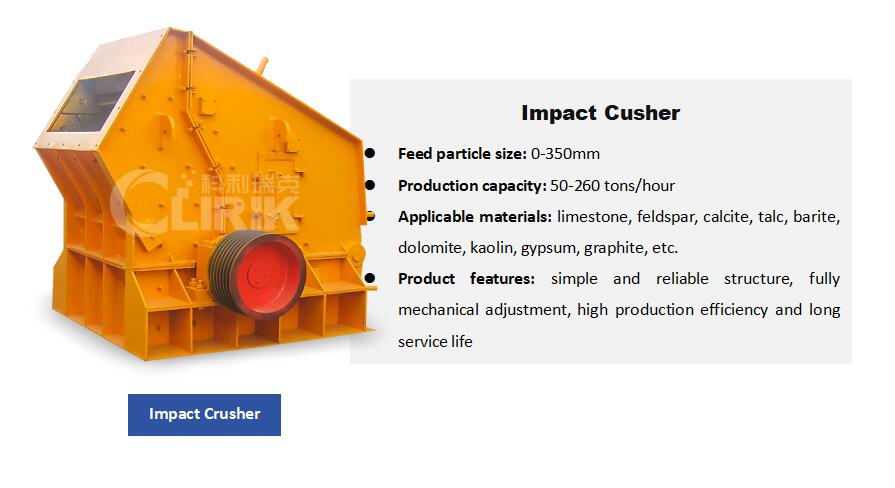

3. Clirik Impact Crusher:

Model: PF Series Impact Crusher

Features:

High reduction ratio and crushing efficiency

No-board connection, easy to disassembly and maintain

Cubic shape of the final product

Suitable for secondary crushing of basalt rock

Clirik Grinding Mills:

1. Clirik Raymond Mill:

Model: YGM Series Raymond Mill

Features:

High grinding efficiency and low energy consumption

Adjustable particle size: 30-425 mesh

Strong integration capability, less ancillary equipment needed

Suitable for grinding basalt to a fine powder

2. Clirik Ultrafine Grinding Mill:

Model: HGM Series Ultrafine Grinding Mill

Features:

Ultra-fine particle size: 325-3000 mesh

High efficiency and low energy consumption

Environmentally friendly with low noise and dust

Suitable for producing ultrafine basalt rock dust

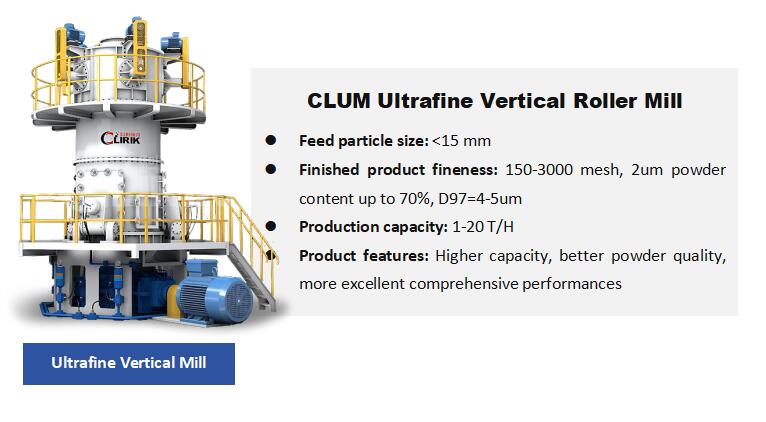

3. Clirik Vertical Mill:

Model: CLUM Series Ultrafine Vertical Mill

Features:

High capacity and low energy consumption

Fine and ultra-fine grinding capability

Integrated with drying, grinding, and classifying

Suitable for large-scale basalt powder production

PRE:Calcite Powder Manufacturing Process

NEXT:没有了!