Shanghai Clirik Machinery Co., Ltd is a large professional manufacturer of Feldspar Raymond Mill,The Clirik Feldspar Raymond Mill have five models: YGM7815,YGM8314,YGM9517,YGM4121,MTM1600.

Output:30- 425 mesh

Shell Size:15-35mm

Grinding Weight:1.2 - 11 T

Application:The Feldspar Raymond Mill is widely used in small and medium mining, chemicals, building materials, metallurgy, refractories, pharmaceuticals, cement and other industries.

Raw Material:such as gypsum, talc, calcite, limestone, marble, barite, dolomite, granite, kaolin, bauxite, fly ash , oxidation iron oxide red, iron ore, etc.

Introduction of Feldspar Raymond Mill

Shanghai Clirik Machinery Co., Ltd is an professional expert Rammond mill manufacturer in China.YGM series Feldspar Raymond Mill is the new type Feldspar Raymond Mill of our company, which is suitable for processing various non-flammable and non-explosive mineral materials with Moh's hardness less than 9.3 and humidity less than 6%. It is widely used in the fields of metallurgy, construction, chemical industry, mining, highway construction etc,. The granularity of the finished powder size can be adjusted between 30 and 425 mesh. Examples of processing materials include quartz, feldspar, barite, calcite carbonate, limestone, talc, ceramic, iron ore, carborundum, bauxite, rock phosphate, coal and other materials, about 400 kinds of materials in total.

Advantage Of Feldspar Raymond Mill:

1.Low production cost, high-performance

Overall for the vertical structure, small footprint, systematic, from raw material delivered to the milling and roughing to final packaging, of an independent production system

2.Good stability, high reliability

Raymond Host transmission device adopts enclosed gear boxes and pulleys, transmission smooth, reliable operation.

3.Perfect particle size

Electrical system adopts centralized control, milling workshop basic enabling unmanned operation.

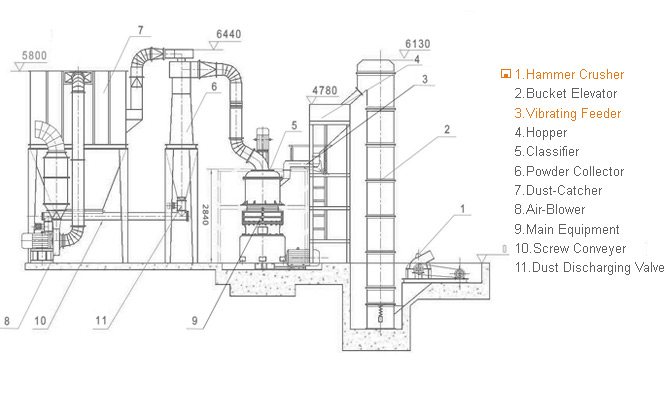

Structure of Feldspar Raymond Mill

Feldspar Raymond Mill is mainly composed of main unit, analyzer, fan, dischargeing cyclone separator, powder cyclone separator and air duct. Among them, the main unit consists of frame, blow shell, shovel, grinding roller and grinding ring.

The rollers tightly rolled on the ring under the effect of centrifugal force. Shovel sends material between the roller and ring and the material is grinded into powder under the high pressure.Then the fan blows the power up into the analyzer. At this time, the power material met the fineness requirement get through the analyzer and get into the power cyclone separator while the others will be sent back for re-grinding.The whole system is airtight circulation.

Feldspar Raymond Mill Main Parts

The main parts of Feldspar Raymond Mill is grinding roller, grinding ring, grinding roller assembly, the plum flower frame, air flue, coupling, perching knife and so on.

Technical Parameter of Feldspar Raymond Mill

| Model | Roller | Ring |

Feeding Size (mm) |

Finished Size (mm) |

Mill System Power (KW) |

Capacity (t/h) |

Overall Dimension (mm) |

|||

|

Quantity (piece) |

Diameter (mm) |

Height (mm) |

Inner Diameter (mm) |

Height (mm) |

||||||

| YGM7815 | 3 | 260 | 150 | 780 | 150 | 15 | 0.613-0.033 | 35.7 | 1-3 | 4300*3500*5100 |

| YGM9517 | 4 | 310 | 170 | 950 | 170 | 25 | 0.613-0.033 | 72.65 | 2.1-5.6 | 7100*5900*7900 |

| YGM1280 | 3 | 370 | 240 | 1170 | 240 | 20 | 0.613-0.033 | 145.15 | 4.5-12 | 9300*5600*8200 |

| YGM1300 | 4 | 410 | 280 | 1270 | 280 | 20 | 0.613-0.033 | 202.15 | 6.5-16 | 9100*8200*8400 |

| YGM1620 | 4 | 450 | 300 | 1500 | 300 | 20 | 0.613-0.033 | 322.2 | 8-20 | 12500*5700*10500 |

| YGM1720 | 4 | 510 | 300 | 1720 | 300 | 35 | 0.613-0.033 | 450 | 10.5-28 | 11550*9500*10500 |

Feldspar Raymond Mill

If you want to know the Feldspar Raymond Mill price or have any questions about Feldspar Raymond Mill, please do not hesitate to contact us.

Phone: 0086-21-20236178 008613917147829

E-mail: sales@clirik.com